News Center

- What are the differences between 304, 304L, 316, and 316L stainless steel pipes?

- What are the surface treatment processes for stainless steel plates?

- How to identify the true and false stainless steel?

- Stainless steel features and classification

- 304 stainless steel sheet factors that stainless steel sheets are corroded

Industry News

Home > News Center > Industry News > What are the surface treatment processes for stainless steel plates?stainless steel plate, hailed as the "metal of the future," is an indispensable material in our modern world. It boasts a remarkable set of properties, including resistance to corrosion, high-temperature endurance, and impressive longevity. However, what truly sets stainless steel plate apart is its ability to adapt its surface, achieving a balance between functionality and aesthetics.

What is stainless steel plate

Before delving into the depths of surface classification, let's grasp the core attributes of stainless steel plate. It's a metal alloy primarily composed of iron, enriched with chromium, nickel, and other alloying elements. These alloying components contribute to its outstanding resistance to corrosion, a defining characteristic of stainless steel plate.

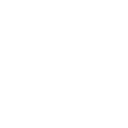

Stainless steel plate surface Treatment

The surface of stainless steel plate is a crucial determinant of its performance and visual appeal. Surface treatments are applied to enhance corrosion resistance, improve cleanability, and provide an attractive finish. Let's explore the primary stainless steel plate surface classifications:

Stainless steel plate BA Surface

The BA (Bright Annealed) surface is among the smoothest finishes, achieved through an annealing process that imparts a highly reflective quality. This surface is used when an exceptionally high-quality appearance is required, such as in the production of upscale kitchen utensils, premium cutlery, and decorative items.

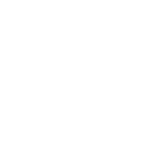

Stainless steel plate 2B surface

Known as the "No. 2B" or "mill finish", the 2B surface is the most common surface treatment. This surface is achieved through cold rolling, resulting in a bright, smooth finish. While it may not achieve a mirror-like gloss, it remains versatile and practical for a wide range of applications. The stainless steel plate 2B surface offers solid corrosion resistance and is widely used in industries where both functionality and aesthetics matter.

Stainless steel plate 2D Surface

The stainless steel plate 2D surface boasts a slightly rougher texture, achieved through hot rolling followed by pickling. It retains some marks from the hot rolling process, making it less smooth compared to the Stainless steel plate 2B surface. Typically, the 2D surface requires additional processing to attain a smoother, more polished look. This surface is often chosen for applications where a less glossy finish is acceptable, such as in the manufacturing of industrial machinery.

Stainless steel plate 8K Surface

The 8K surface is renowned for its high reflectivity and mirror-like appearance. Achieved through meticulous polishing and buffing, it results in a surface that can reflect images with clarity. This surface is favored for applications demanding superior decorative appeal, including high-end kitchen appliances, architectural elements, and luxury decor.

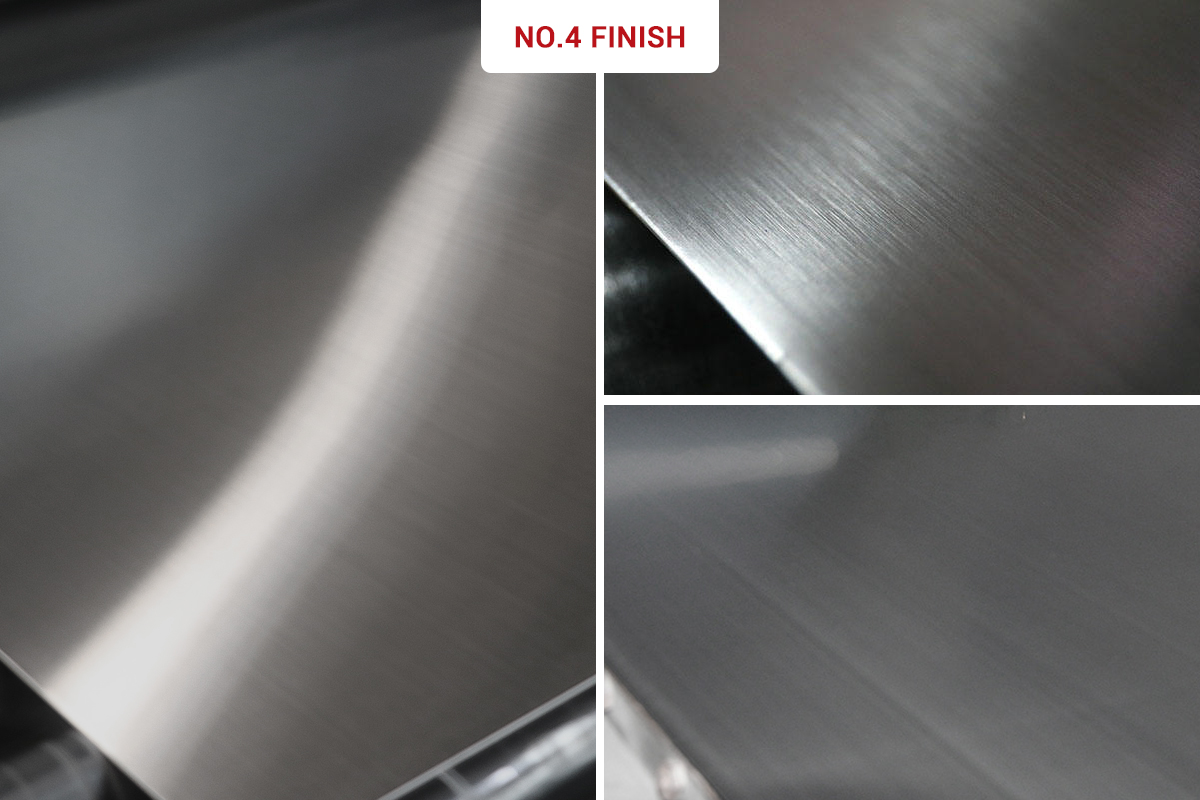

Stainless steel plate No. 4 Surface

The No. 4 surface is created by brushing or polishing, resulting in a consistent, fine-grained texture. It offers a balance between a smooth finish and a muted shine. This surface is commonly used in both decorative and industrial settings, such as handrails, architectural accents, and equipment surfaces.

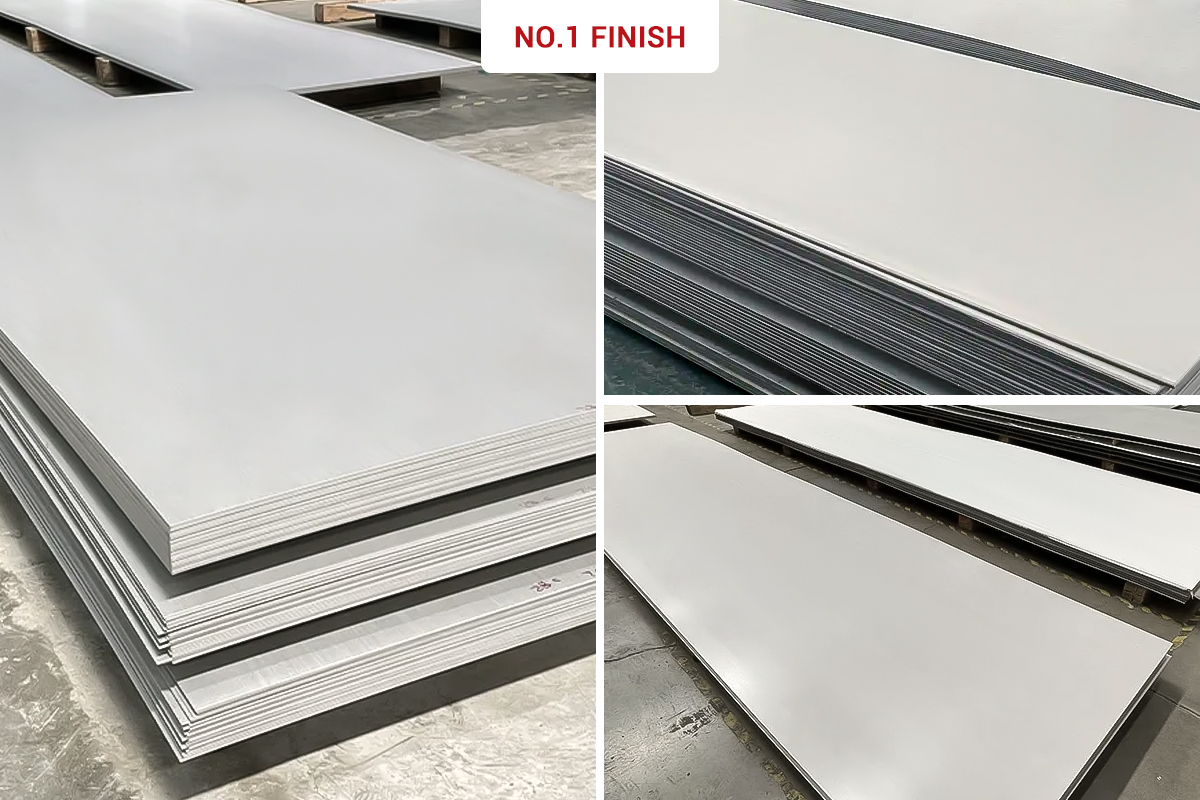

Stainless steel plate No. 1 Surface

The No. 1 surface is obtained through hot rolling, which can leave a rougher texture. It's suitable for applications where the primary focus is on functionality rather than aesthetics. Industries that prioritize durability and structural integrity often opt for the No. 1 surface.

Stainless steel plate surface applications

The choice of stainless steel plate surface classification depends largely on the intended application. For instance, the stainless steel plate 2B surface and stainless steel plate 2D surface are practical choices for machinery and industrial equipment, thanks to their corrosion resistance and cost-effectiveness. In contrast, the 8K and BA surfaces are well-suited for high-end consumer products and architectural elements that demand a sleek and reflective finish.

In the construction industry, stainless steel plates with the No. 4 surface are frequently employed for handrails, façade cladding, and other decorative elements. The stainless steel plate No. 1 surface is popular in heavy-duty environments such as chemical processing and manufacturing, where durability takes precedence.

In Conclusion

In the realm of stainless steel plate surface, classification is pivotal to both functionality and aesthetics. Whether you're designing a modern kitchen, constructing an architectural masterpiece, or manufacturing industrial machinery, understanding the different surface treatments and their applications is crucial for making the right choice. Each classification brings its own unique attributes, striking a balance between durability and aesthetics, and contributing to the versatility of stainless steel plate in various industries. By selecting the appropriate surface finish, you can ensure that your stainless steel plate components not only withstand the test of time but also shine in their intended roles.